HOT WORK STEEL (H-13)

Wellington Hot Work Steel is best general purpose tol steel grade for Hot Work applications. Furnished with a "soft Anneal". Wellington Hot Work Steel is delivered at approximatley 207 BHN. This grade offers excellent "Red Hardness", i.e. retains hardness at elevated temperatures. Displays excellent shock resistance and abrasion resistance. Wellington Hot Work Steel can withstand drastic temperature changes while in service.

WELLINGTON HOT WORK STEEL

Heat is a formidable enemy of any alloy or tool steel. Alternating temperatures or severe temperature change in service are the worst. Wellington Hot Work Steel withstands "Thermal Shock" and retains toughness and wear resistance in the most severe of these circumstances.

APPLICATIONS

Hot Work Applications

Hot Shear Blades

Extrusion Press Tooling

Zinc and Aluminum Die Casting Dies

Punches

Piercers

Mandrels

Shear Blades

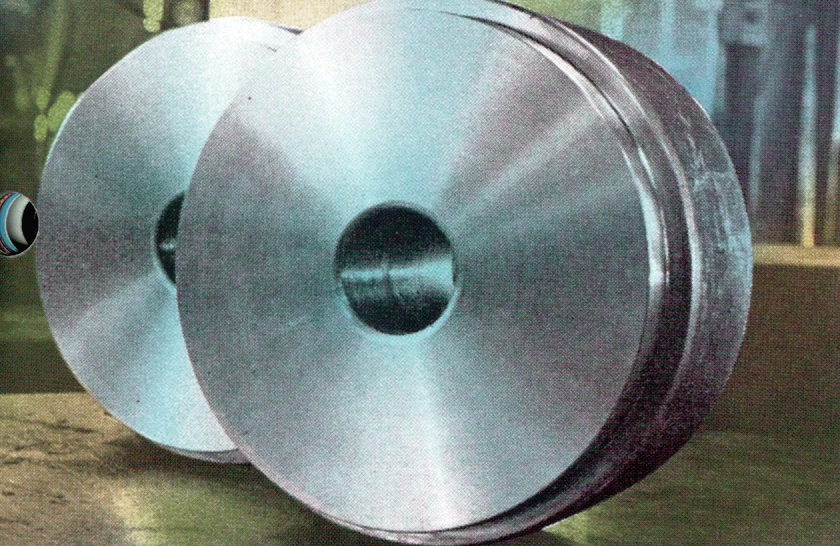

SIZE RANGE

Rounds to 36" dia

Heavy plate and flat sections

|

HEAT TREATING

Forging

2050 F to 2150 F

Stop at 1850, Cool Slowly Preheat Slowly 1300-1500 F

Annealing

1600 F Furnace Cool, average 207 BHN Furnace Cool 30 /hr. to 900 Then Air Cool

Hardening

1850 F Air Quench Temper 1050 to 1150 Average RC-40-50 (Recommended for die casting dies; 44-48RC)

ADVANTAGES

Ease of Machining

No special precautions. Machine at the annealed hardness od 207 BHN. Machine rated at 75% that of carbon steel.

Consitant Response to Heat Treatment

Retains Hardness at Elevated Temperatures

Resists Thermal Shock

Highly Impact Resistance

Resists Sudden Torque

High Thermal Conductivity

Non Deforming

Die Casting Dies should be hardened 40 4-48 RC. Do not use higher than RC.

Tempering Temperature F

400

1000

1100

1200 |

Rockewll

C

54

52

48

37 |

|